IMFO®

Integrally molded for major hazard control

Traditional tank maintenance can be a challenge with many chemicals – so Poly has developed a unique system that helps minimize the hazards associated with traditional vertical tank maintenance.

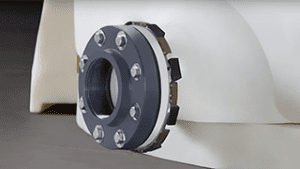

Poly Processing’s Integrally Molded Flanged Outlet (IMFO®) Tank, is a homogenous flange system that is molded as part of the tank while it is being manufactured, making it a stress-free part of the tank. The flange is created from the same material as the tank — it’s not an insert added during or post-production.

Some companies create tanks out of one substance and insert a metallic flange post-production, for drainage and discharge. This is simply to save money on investing in proper tooling to make the right tank. An inserted metallic flange unfortunately is common in the tank industry, but there are critical benefits to using a molded full discharge fitting or IMFO.

Advantages of IMFO®

Advantages of IMFO®

- Full tank discharge, because the flange is at the bottom of the sidewall, below the tank knuckle radius. There’s no need to enter the tank for cleaning.

- Enhanced long-term performance and greater useful life of the tank since the flange doesn’t compromise the tank’s hoop integrity or structural design.

- Complete flange face protection in aggressive oxidation environments. The antioxidant OR-1000™ system protects the discharge components from deterioration.

- Highest amount of static head pressure. The IMFO’s design brings you the highest net positive suction head (NPSH) of any vertical non-coned tank on the market.

- Any required maintenance is simple and hassle-free. Unlike metallic inserts, the flange extends away from the tank wall and the entire flange system is external with easy hardware access from outside the tank.

- There are no chemical compatibility issues like the ones you may encounter with metallic inserts. If the chemical is safe in a crosslinked polyethylene tank, it’s safe discharging out of the IMFO system.

Click here to go our Vertical Tanks with IMFO offering page