Venting

Protect your chemical storage tank system by ensuring your venting is set up properly. Here’s a look at our Do’s and Don’ts when it comes to venting.

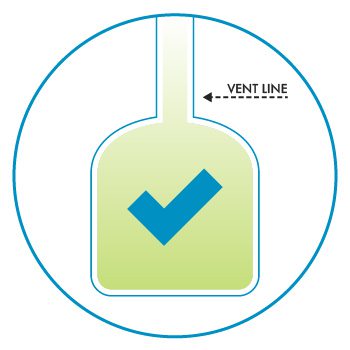

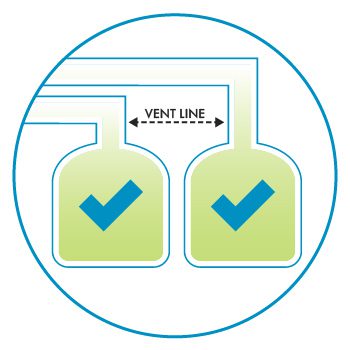

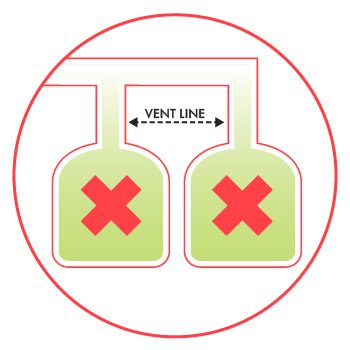

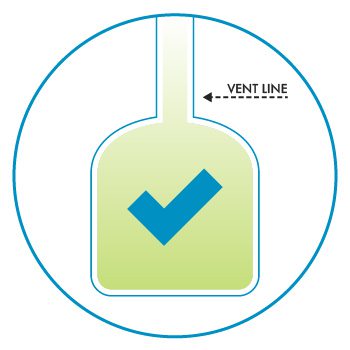

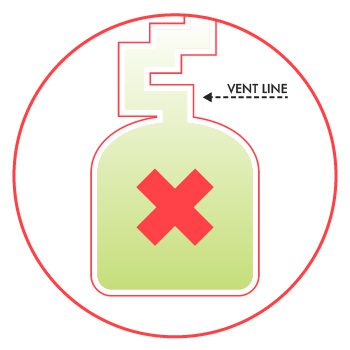

1. Do Not Pipe Multiple Vents Into a Common Line

If a common line is used, contact Poly Processing to ensure proper vent size.

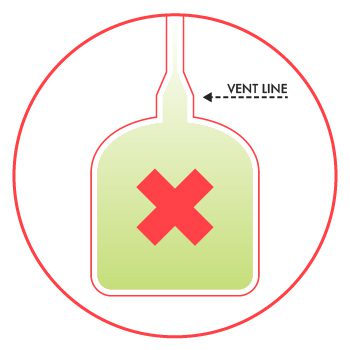

2. Do Not Reduce Vent Size or Vent Line

3. Keep 90 Degree Bends to a Minimum – 3 or Less Are Recommended

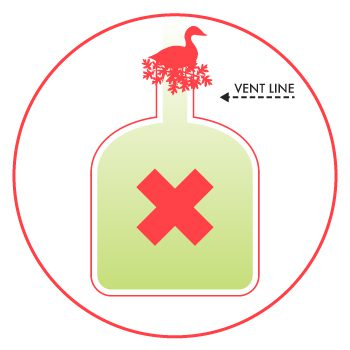

4. Keep Vent Lines Clear of Restrictions

Venting charts based on recommendation and criteria from Venting Design for ACFM Technical Paper.

| Mechanical Pump Fill | Pneumatic Fill | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| IF ≤ 1,000 gallons | IF – Vent length ≤ 3′ | IF – Vent length > 3′ and ≤ 30′ | IF – Scrubber or fume tight application | ||||||

| ✔ Vent size should equal size of largest fill or discharge fitting | ✔ Maintain vent screen mesh size ≥ 1/4″ or no screen used | ✔ 3 or less 90º elbows with no other restrictions or reduction in pipe size | ✔ Vent pipe size throughout scrubber system CANNOT be reduced! | ||||||

| ✔ Centerline of dispersion pipe not to be submersed > 6″ | |||||||||

| IF > 1,000 gallons | ✔ Emergency Pressure Relief Cover Required IF > 1,000 gallons | ✔ Emergency Pressure Relief Cover Required IF > 1,000 gallons | ✔ Perforated dispersion pipe must be same diameter as vent or larger. Sum of perforations ≥ cross-sectional area of pipe | ||||||

| ✔ Vent size should exceed the largest fill or discharge fitting by 1″ | |||||||||

| Tanker Discharge | Inlet/Fitting Size | Minimum Vent Size | Tanker Discharge | Inlet/Fitting Size | Minimum Vent Size | Tanker Discharge | Inlet/Fitting Size | Minimum Vent Size | |

| 2″ | 2″ | 4″ | 2″ | 2″ | 6″ | 2″ | 2″ | 6″ | |

| 3″ | 2″ | 6″ | 3″ | 2″ | 6″ | 3″ | 2″ | 8″ | |

| 3″ | 3″ | 6″ | 3″ | 3″ | 8″ | 3″ | 3″ | 10″ | |